Effective Process Safety and Risk Management

Effective Process Safety and Risk Management

Recent, unfortunate processing industry events spotlight the importance of process safety and risk management in all project phases. In reality, lives, the environment, and business viability depend on how well process safety and risk management are integrated into the design, construction and commissioning of plant modifications and new process units.

Nexus is committed to helping its clients effectively meet their project’s short and long-term Process Safety Management (PSM) compliance requirements. Developing project plans and strategies based on a realistic assessment of risk is not only critical to meeting OSHA and EPA requirements, but more importantly to protecting individuals and the environment. At the same time, it’s good business practice.

Addressing these critical challenges cannot be a check-in-the-box exercise carried out by the project team. A solid approach requires skill, experience, and creativity. A team of the right professionals with the appropriate skills, processes, and tools and a keen appreciation of project and operational challenges is essential for success.

In summary, taking on the challenges of process safety and risk management requires:

- Respect for, and appreciation of, process safety and risk management by project team

- Collaboration of business, project, construction, operations, and PSM leaders

- Engineering skill, experience, and creativity

- Systematic application of the Front End Loading (FEL) process

- A rigorous quality assurance, completions, and turn over system

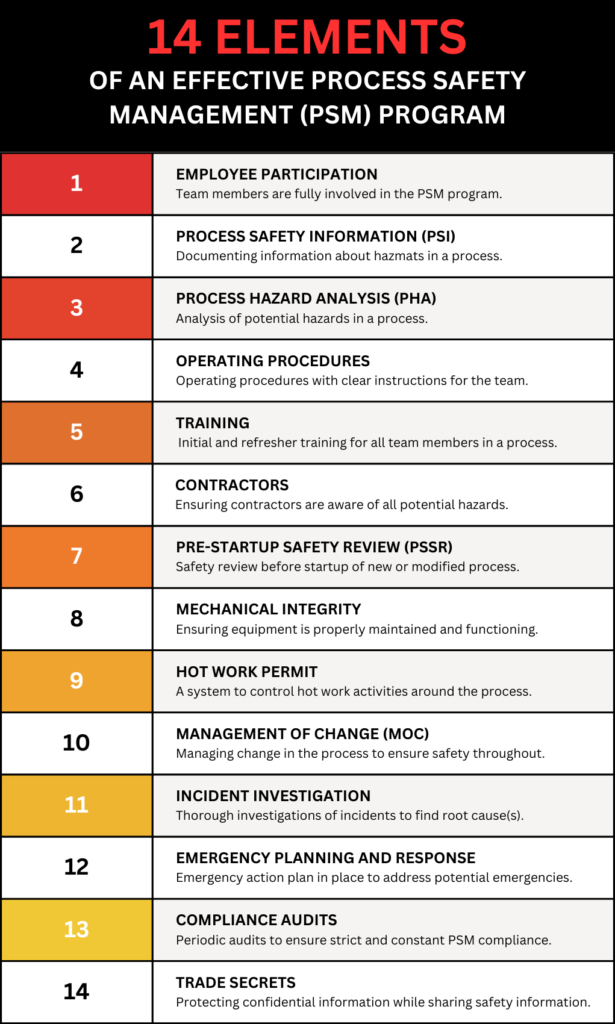

Elements of an Effective PSM Plan

The process safety management system program is divided into 14 elements. The U.S. Occupational Safety and Health Administration (OSHA) 1910.119 defines all 14 elements of the process safety management system plan.

All elements mentioned are interlinked and interdependent. Each is related and necessary to make up the entire PSM picture.

Forward thinking to integrate projects into ongoing PSM compliance systems reduces project timelines, expedites commissioning and start up, and reduces project investment costs. Too many times, teams do not plan ahead and then are forced to scramble at the end of the project.

Nexus has a successful track record of supporting client teams in planning, integrating, and implementing project PSM activities with ongoing plant compliance and operational systems. Our skilled professionals bring the engineering expertise along with plant operations, quality assurance, and construction experience needed to support the effort. Our tools include a systematic approach to risk management, inherently safer design principles, quality assurance, and completions programming. Our group has the teamworking skills essential to developing ideas for effective solutions.

Summary

Comprehensive Process Safety Management compliance planning based on rigorous risk management results in better project and operating safety performance, reduced environmental impact, and improved return on project investment.

Nexus professionals have the interpersonal skills, tools, and experience our clients value in supporting their project PSM compliance strategies.

We are proud of our project PSM support track record and look forward to discussing our capabilities with you.

For more information, visit www.nexusegroup.com or call us at (216) 404-7867.