Success Stories > Nexus Advances Sustainability Agenda with 15MW Combined Heat and Power Development

Nexus Advances Sustainability Agenda with 15MW Combined Heat and Power Development

Nexus provides expertise on Gas Turbines and Heat Recovery Steam Generators (HRSG) systems to reduce electrical supply costs and improve profitability and efficiency.

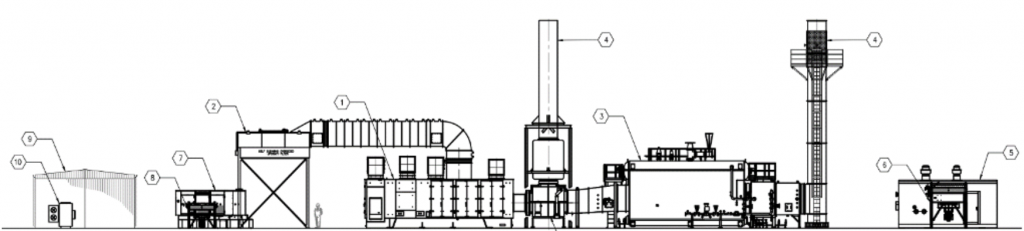

Solution leveraged two 7.5MW Combustion Gas Turbines and Heat Recovery Steam Generators (HRSG).

Solution leveraged two 7.5MW Combustion Gas Turbines and Heat Recovery Steam Generators (HRSG).

Combined heat and power (CHP) systems are playing an important role in providing large scale efficiency gains by repurposing waste heat from power generation to meet a facility’s electrical and thermal load demands. When integrated into the facilities main power grid, added reliability and resilience are provided in the event of a utility power outage. For this project, a conceptual design was developed that provides 15 MW of power generation to reduce electrical energy supply costs, improve profitability and energy efficiency while maintaining a high level of of electrical and steam supply reliability.

Challenge

Nexus was challenged with evaluating and sizing of steam generation from the CHP units that would displace steam generated by two existing utility boilers and the waste heat steam generation within the plant. The design required balancing the overall electrical and steam generation being produced within plant operational parameters to rely less on the electrical grid and be more sustainable, while providing for a cost-effective solution and a positive return on investment.

Solution

Nexus provided technical expertise needed by the owner to define the project scope and develop conceptual process and the electrical design basis parameters. Nexus also gathered specific equipment pricing which included gas turbines, heat recovery steam generators, gas compressors, electrical paralleling switchgear and powerhouse, black start generator, and CEMS/CHP system controls. The Project Team chose a two-train CHP/HRSG design to provide improved reliability to the plant. A trip of one turbine, providing 7.5 MW of generation, was felt to be within the ability of the current utility provider to handle the load shift without interfering with current facility operations.

Client Name

Confidential

Location

Midwest USA

Industry

Refining

Services

- Conceptual Engineering and Design Basis Input

- Process Heat Balance Study

- Power System Analysis

- Specification of Balance of Plant (BOP) Major Equipment

- Major Equipment Vendor Review and Coordination

- Layouts, Code, Site Access, and Performance Reviews

- Total Installed Cost Estimate (TIC)

- Final Study Detailed Report