Oscar Kropp, Refining and Chemical Industry Pioneer

Industry Pioneer and Nexus Family Connection

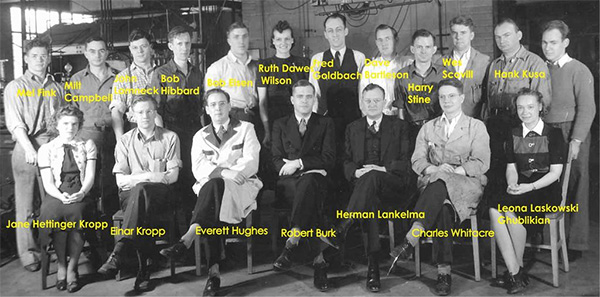

John Kropp, Nexus Structural Engineer, introduced us to a true refining and chemical industry pioneer in June. John’s father Oscar joined us for lunch for a unique and fascinating look back at our industry, key processing breakthroughs and the leading players. We’re happy to share some of what we learned with you.

Oscar is from the “greatest generation” of chemical engineering innovators. Using hand calculations, slide rules and charts, he worked with other great minds to make spectacular impacts in process engineering and environmental protections – many of which are still in practice today.

After graduating with a chemical engineering degree from Michigan State in 1937, Oscar started his career with The Standard Oil Company, Ohio (SOHIO) working in its research laboratory on the Western Reserve campus. Oscar noted his good fortune with his first job out of college. He quipped that most of his classmates who graduated in the depths of the Great Depression were pumping gasoline.

In the mid-1930s, when Oscar began his SOHIO career, oil refining mostly consisted of a thermal cracking and distillation processes. Little physical property data was available to design processing equipment.

The laboratory experiments in which Oscar participated were used to guide the design of distillation columns and other equipment. Once built, the equipment was tested to determine if the results matched the actual production data. If not, the equipment was repurposed for other uses.

During this time, Oscar came to know of inventors Jesse A. Dubbs and his son Carbon Petroleum (C. P.) Dubbs. The Dubbs and their patents became part of the Universal Oil Products Company (UOP) started by J. Ogden Armour, a meat packer from Chicago. Armour provided the initial seed money and kept the firm going through its first years as it lost money. Most of the losses were incurred during lengthy legal battles with petroleum firms, including Esso, which used technology competing with Dubbs.

Once the U.S. joined World War II in 1941, Oscar and the SOHIO research and engineering team were required to work seven days per week. Their work supported the war effort with the development of the alkylation process and methods for recovering benzene.

Alkylation was used to produce high octane fuel for fighter airplanes while benzene was used for producing explosives. The first SOHIO alkylation unit was constructed at the company’s Toledo refinery, which is still in operation today.

Oscar participated in the development of other refining process improvements following the war, including the Fluidized Catalytic Cracking process (FCC) which is still a mainstay of refining today.

In the early 1950s, Oscar, as SOHIO’s representative to the American Petroleum Institute (API), worked along with other oil company engineers to reduce the environmental footprint of oil refining. Oscar was instrumental in the development of the API separator used to separate oil from refinery wastewater. The API separator is still in use today as the first step in most refinery wastewater treatment processes. Oscar also worked to tackle other local environmental air and water challenges in Cleveland.

At the same time, Oscar worked with the SOHIO team to successfully transform a laboratory discovery into a commercial operation to produce acrylonitrile, a valuable building block for other chemicals and acrylic fibers. The team produced acrylonitrile on a commercial scale while launching a chemical company. Proceeds from licensing and producing acrylonitrile helped fund SOHIO’s Alaskan Pipeline in the 1970s.